Voltage vs. Current: Mastering Fundamental Electrical Concepts for Optimal Design

Demystify voltage and current, understanding their core relationship and how these critical electrical parameters profoundly influence equipment selection and overall system design in industrial and commercial applications.

In the world of electricity, voltage and current are two fundamental concepts that often get confused but are distinct and critically important. Understanding their individual roles and their interdependent relationship is essential for effective electrical system design, equipment selection, and troubleshooting in any industrial or commercial setting.

Core Electrical Concepts Explained

-

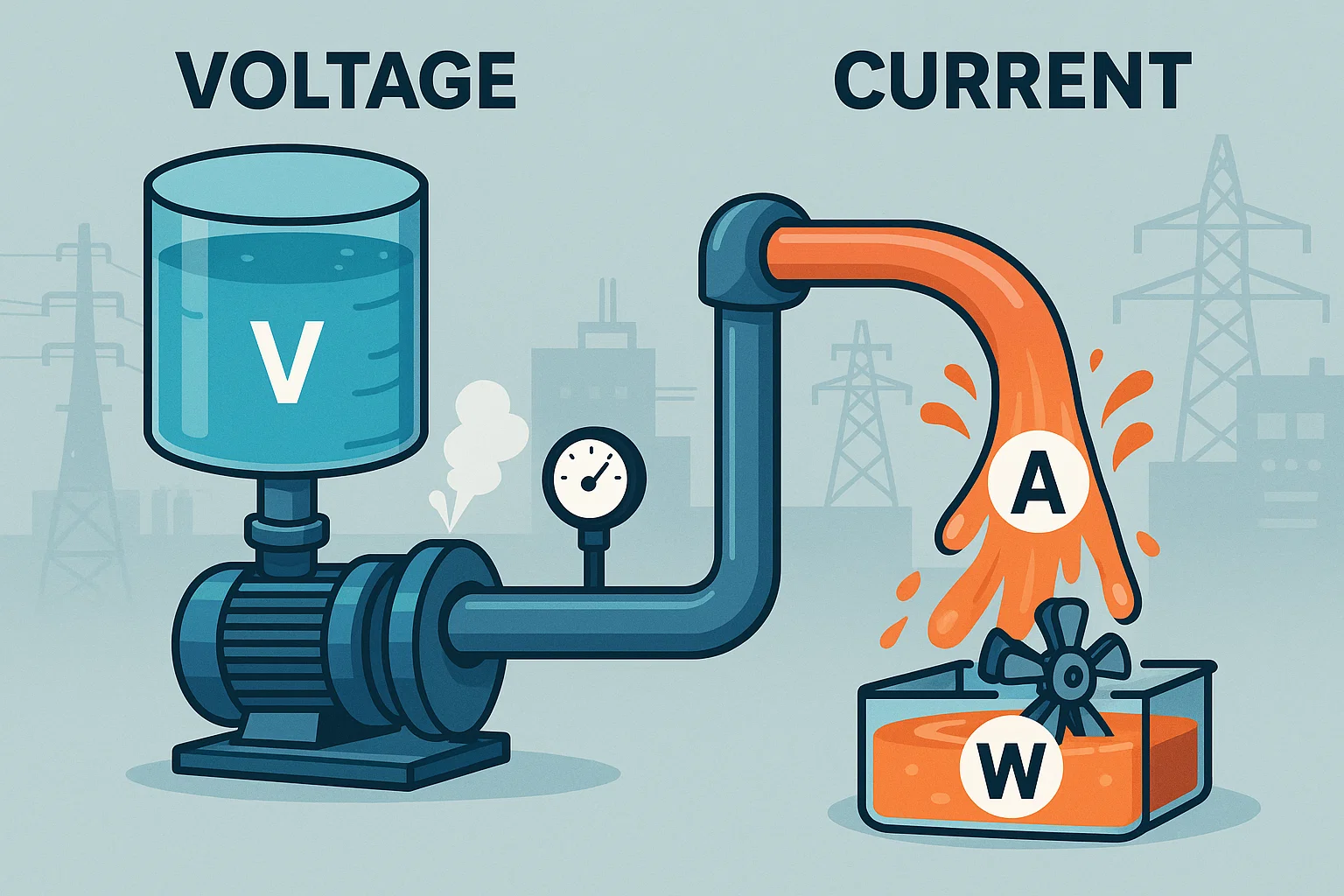

Voltage (V): The Electrical "Pressure"

Voltage, often measured in Volts (V), is the electrical potential difference or the electromotive force (EMF) that pushes electrical charges through a conductor. Think of it like water pressure in a pipe: higher voltage means greater "pressure" to drive electrons. Without voltage, there is no push for current to flow. -

Current (I): The Electrical "Flow Rate"

Current, measured in Amperes (A or amps), is the rate of flow of electrical charge (electrons) through a conductor. Following the water analogy, current is the volume of water flowing through the pipe per unit of time. The amount of current depends on both the voltage applied and the resistance of the circuit. -

Power (P): The Rate of Doing Work

Power, measured in Watts (W), is the rate at which electrical energy is converted into another form (like heat, light, or mechanical motion). For a simple DC circuit or a purely resistive AC circuit, power is directly calculated as the product of voltage and current:P = V × I

In AC circuits with inductive or capacitive loads, the concept of Power Factor becomes crucial, as it indicates how much of the apparent power (VA) is real power (W) doing useful work.

Implications for Electrical System Design

The relationship between voltage and current has profound implications for how electrical systems are designed and operate:- Conductor Sizing and Losses: Higher current levels require larger diameter conductors (wires and cables) to safely carry the charge without overheating. Critically, higher current also leads to greater I²R losses (Joule heating), where energy is wasted as heat in the conductors. This means lower efficiency and increased operating costs.

- Efficiency and Transmission: For a given amount of power, increasing the voltage allows the current to be proportionally reduced (P = V × I). This is why electricity is transmitted at very high voltages over long distances – to minimize current, thus minimizing I²R losses and allowing for smaller, lighter conductors.

- Insulation and Safety: While higher voltage can be more efficient, it also requires greater insulation and larger clearances between conductors to prevent arcing and ensure safety. This translates to higher material costs and more stringent safety protocols.

- Component Ratings: Every electrical component (resistors, capacitors, switches, motors) has specific voltage and current ratings that must not be exceeded to prevent damage or failure.

Equipment Selection Best Practices

Choosing the right equipment involves carefully considering both voltage and current parameters:- Match Voltage Ratings: Always ensure the voltage rating of equipment matches the supply voltage, accounting for permissible tolerance ranges. Operating equipment outside its specified voltage range can lead to poor performance, inefficiency, or damage.

- Account for Inrush Current: Motors, transformers, and certain power supplies can draw significantly higher "inrush" currents momentarily when first switched on. Overcurrent protection devices (breakers, fuses) must be sized not just for continuous operating current but also to withstand these temporary peaks without nuisance tripping.

- Consider Continuous Operating Current and Duty Cycle: Select conductors and protective devices based on the equipment's continuous full-load current. Also, consider the duty cycle (how often it runs and for how long) and ambient temperature, as these affect how much heat a conductor can safely dissipate.

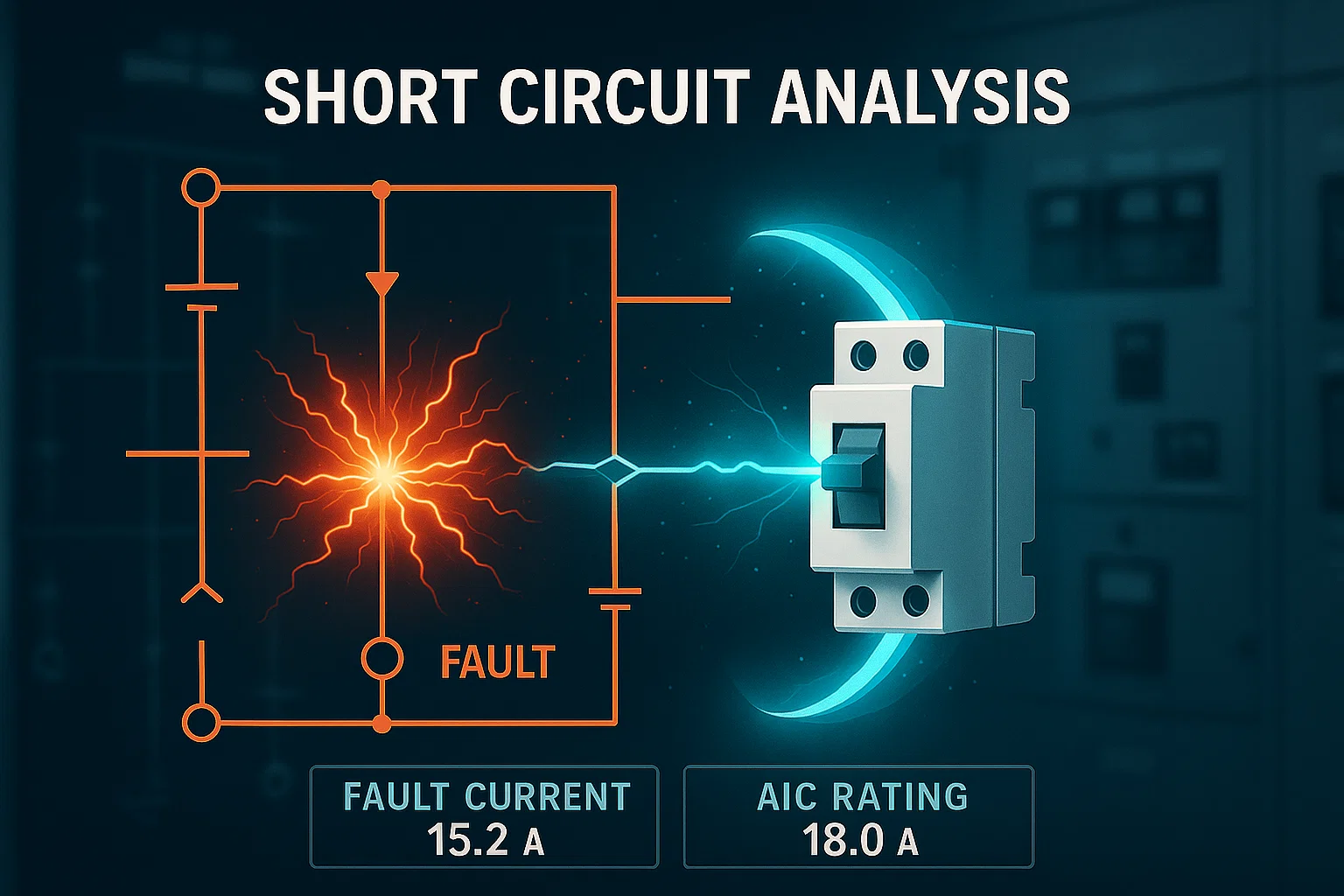

- Evaluate Short-Circuit Current Capacity: All components, especially protective devices, must be rated to safely interrupt or withstand the maximum potential short-circuit current that could occur at their location in the electrical system.

- Consult Nameplates and Specifications: Always refer to the manufacturer's nameplate data and technical specifications for precise voltage, current, and power ratings, along with any special installation requirements.

🚀 The Bottom Line: A thorough understanding of voltage and current is foundational to designing safe, reliable, and efficient electrical systems. By carefully matching equipment to electrical parameters, you can minimize energy losses, prevent premature failures, ensure protective devices function correctly, and optimize overall operational performance.